say hello to your next

HOW IT'S MADE

MID-FIRE Δ5/6

STONEWARE

Lightly textured with a moderate amount of firmness, this stoneware is easy to throw but smooth enough for handbuilding.

For the best results, bisque to Cone 04 then glaze to Cone 5.

SHRINKAGE

11.7%

ABSORPTION

2.8%

COE x 10-6

4.8

LOW-FIRE Δ04/06

EARTHENWARE

Perfect for low-fire studios and schools who want to stock a single "do it all" clay -sculpture, throwing and handbuilding. We’ve replaced traditional grog with a light fiber for improved adhesion, strength, and surface finish.

For the best results, bisque to Cone 04 then glaze to Cone 06.

SHRINKAGE

6.5%

ABSORPTION

13.82%

COE x 10-6

4.6

FIRE RANGE Δ06/6

SLIP

Slip is a flexible slip base that can be modified with mediums to create the right consistency and applied to clay for slip trailing, painting, piping, sgraffito and low-relief techniques.

For the best results, apply to greenware. Bisque to Cone 04 then glaze to Cone 06. Can be fired up to Cone 6. Always test.

Things to know

Colored Clay + Slip

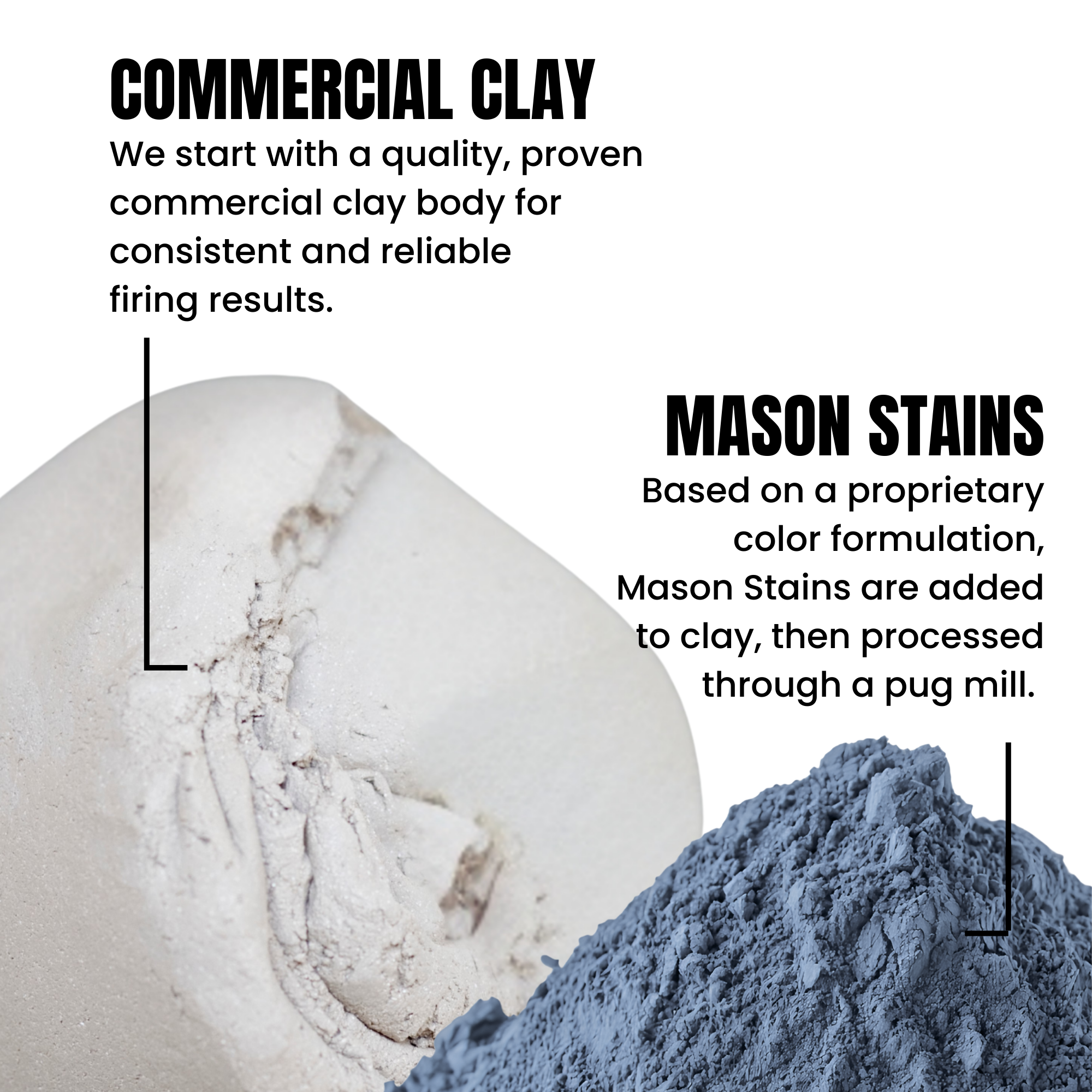

Colored Clay is a white clay body tinted with Mason® stains (ceramic pigments) dispersed throughout the clay.

Colored Slip is a smooth clay‑based coating colored with Mason stains for painting, detail work, or screen printing on greenware or bisque.

Many commercial underglazes are formulated the same way—clay + stain + small additives for brushability—using the same pigment families (including encapsulated/inclusion reds/oranges/yellows).

Product Use + Storage

Colored Clay:

- Colored clay can be used for handbuilding or throwing of functional, decorative and sculptural works. Not recommended for children.

- Colored clay can be mixed together to create new colors, mixed with white clay for tints, brown for tones and black for shades. If mixing with other clay bodies, check for compatibility before using in work.

- Store clay in an airtight bag. If clay is too dry or dries out, add no more than 40% water and let stand overnight to rehydrate.

- Like all clay, mold may also grow on colored clay. This does not mean the clay is no longer good. There are many tips and recommendations online to address mold.

Colored Slip:

- Colored slip is used to apply color to leatherhard clay.

- To apply, dip greenware into colored slip or paint with a brush.

- Colors can be used alone or mixed together. The color of the unfired colored slip is typically close to the finished results after firing.

- Close lid tightly after use to prevent colored slip from thickening or drying out. If colored slip is too thick, add one drop of Darvan 7/811 at a time, mixing in between until desired consistency is achieved; use sparingly.

- Greenware with colored slip (no glaze) does not need stilted.

About Ceramic Stains

Colored clays and colored slips are made with Mason® ceramic stains. Mason states no lead compounds are used in manufacturing their pigments.

Like other commercial ceramic products, some warm colored ceramic stains may use encapsulated (inclusion) Cd‑Se pigments, which are widely used in ceramic glazes. Use of inclusion stains are included in product description if applicable.

Handle powders responsibly; avoid dust; consult SDS for all materials.

Clay + Glaze Compatibility

Always run a small test before using clay and/or colored slips before using for work.

Glaze Compatibility

- Colored clays and slips are compatible with most commercial glazes. Use low-fire glazes (cone 05/06) for earthenware clay and mid-range glazes (cone 5/6) for stoneware.

- Glaze appearance may vary and change in color, value and tone based on color of clay, glaze, thickness of glaze application, the firing process, and temperature.

- Use zinc-free or glazes compatible with chrome-tin pigments as noted in the product description if applicable.

Clay Compatibility:

- Our colored clays can be mixed and/or used together.

- Some combinations may be create unexpected color results.

- We do not have any reported compatibility issues when mixing our clays with other commercial clay bodies of similar type and shrinkage and COE.

In general, if slip has a different shrinkage rate than the clay body, it may flake off. If glaze, however, has a lower shrinkage rate than the clay body, the result is called crazing, a process that produces fine cracks on the surface. The opposite, shivering, is when glaze comes off the vessel or cracks it. Test and adjust as needed.

Dinnerware Safety

Ceramic stains are industry‑standard pigments and encapsulated (inclusion) colors; like all handmade pottery, finished ware intended for food contact should be lined with a compatible, food and dinnerware-safe glaze and tested for dinnerware safety.

Safety Data Sheets (SDS)

Our colored clay and slip consist of commercial clay bodies mixed with industry standard ceramic stains.

Safety Data Sheets (SDS) for ceramic stains and the commercial clay bodies can be found on our website: https://smashedstudio/pages/sds

Product descriptions include links to the SDS for the specific clay bodies and ceramic stains used. Handle powders responsibly; avoid dust; consult SDS for all materials.

MUST HAVE TOOLS

Clay Cutters